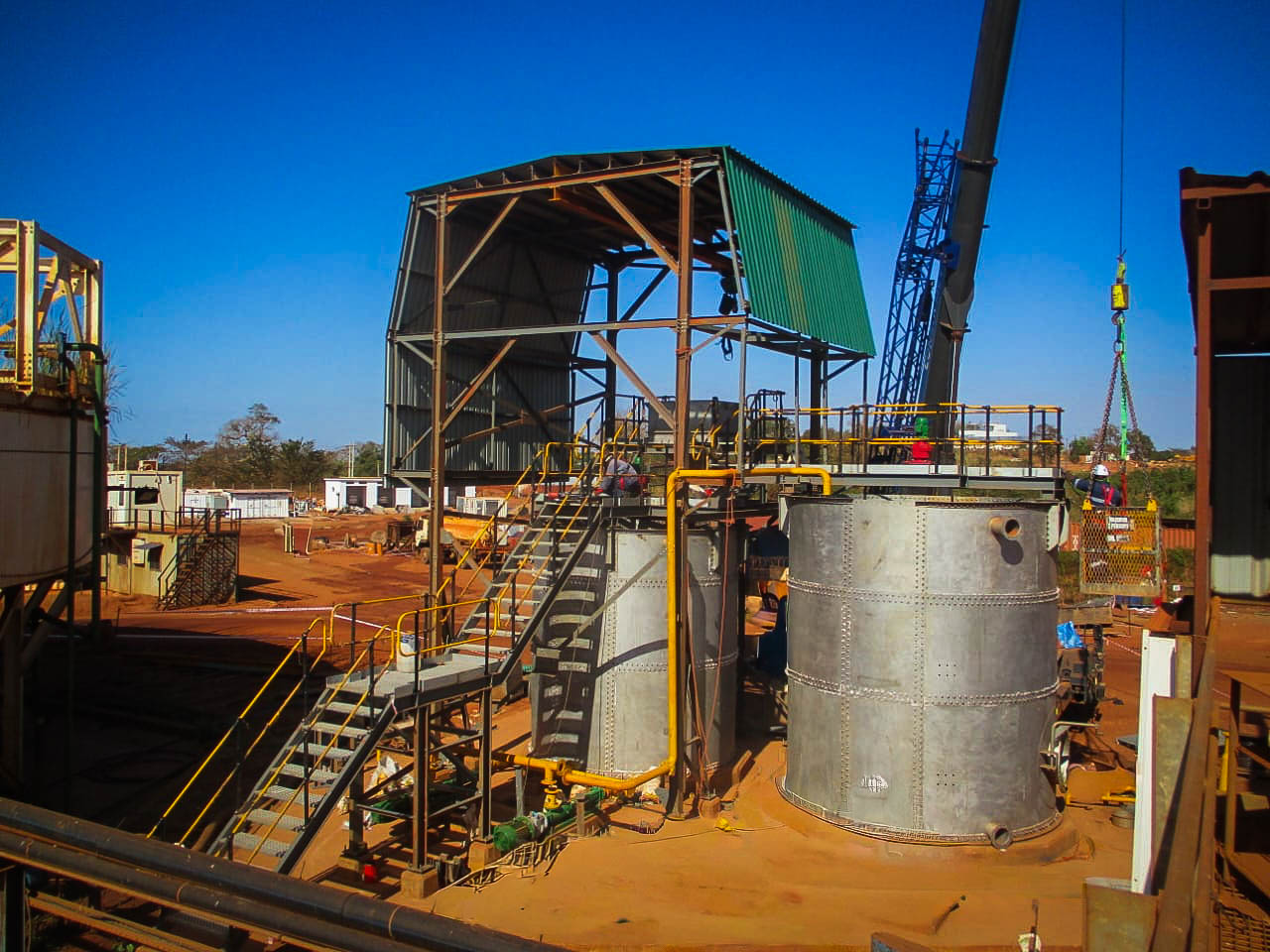

Reagent Plants

Precision reagent makeup and dosing systems for flotation, coagulation, pH control, and chemical

conditioning

UNDER CONSTRUCTION

Overview

Cube Consolidating Reagent Plants provide custom-engineered systems for safe reagent storage, hydration, mixing, and dosing across water, mining, chemical, and other process industries. They can operate as standalone units or integrate seamlessly into larger treatment trains, meeting precise reagent types, hydration needs, and flow requirements.

Available in a range of sizes, these plants offer various bulk storage options and are designed around specific volumetric flow, retention, and hydration times to ensure reliable, efficient performance for any process application.

Technical Highlights

- Typical make-down solution concentration: 0.05–0.5% (0.5–5 g/L) depending on reagent type.

- Hygienic and accurate dosing with flow metering and feedback control—often via ultrasonic or viscosity sensors

- Modular design supports up to hundreds of kilograms per hour hydration capacity in skid format

Key Features

Reagent plants convert solid or liquid chemicals into precise, process-ready solutions with automated hydration, mixing, and dosing for consistent performance.

- Automated Dosing

- Consistent Mixing

- Accurate Sequencing

- Flexible Integration

Key Benefits

Reagent plants ensure precise, automated dosing for consistent reagent quality, compact installation, and compatibility with a wide range of chemicals.

- Accurate Dosing

- Consistent Quality

- Compact Design

- Broad Compatibility

Industries Where Reagent Plants Are Used

Cube Consolidating reagent systems serve numerous sectors:

- Mining, especially flotation circuits requiring precise collector dosing (e.g. sodium or potassium xanthates)

- Water & Wastewater Treatment, involving pH control or coagulation steps

- Food & Beverage, Pharmaceuticals, Agriculture, and Pulp & Paper: for chemical addition in clarifying or product processing

- Chemical, Petrochemical, and Materials Handling: where reagent use and recovery is critical